How High Pressure Misting Systems Work and Why They Scale for Commercial Parks

What Defines a High-Pressure Misting System in Commercial Applications

High pressure misting systems for commercial use run around 1000 PSI, breaking water down into tiny droplets under 50 microns in size (that's 0.05 mm). This creates fast evaporation while keeping surfaces mostly dry. These aren't your basic backyard systems though. They come equipped with heavy duty parts like stainless steel pumps, special tubing that stands up to UV exposure, and nozzles designed to resist clogging issues. A recent industry report from 2024 shows some impressive numbers too. Parks that install these commercial grade systems can expect temperature drops between 18 and 25 degrees Fahrenheit in arid areas. That's actually more than twice what most home systems manage, which typically only cool things down by 8 to 12 degrees. Makes sense when you think about the quality difference in equipment.

Key Differences Between Residential Patios vs. Commercial Spaces: Scalability and Design Requirements

| Factor | Residential Systems | Commercial Parks |

|---|---|---|

| Operating Pressure | 40–300 PSI | 800–1,200 PSI |

| Material Durability | Polymer tubing | Stainless steel piping |

| Coverage Area | ≤ 500 sq. ft. | Up to 10+ acres |

| Maintenance Cycle | Annual inspections | Quarterly nozzle replacements |

Commercial installations require redundant pumps and zoned controls to maintain consistent cooling across large or uneven areas, ensuring reliability during peak usage.

Core Components: Pump Setup, Line Routing, and 1,000 PSI Pressure Needs

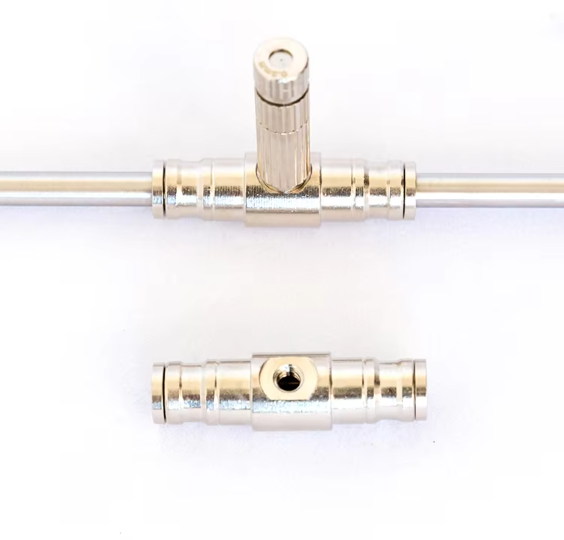

Triplex plunger pumps form the core component for most commercial systems these days. These pumps can handle pressures around 1,000 PSI consistently during several 12 hour shifts without showing signs of wear or reduced efficiency. The stainless steel tubing used typically has bore sizes between half a millimeter to seven tenths of a millimeter, which helps maintain pressure when running across lengthy pipe runs. For nozzle placement, installers generally space them out somewhere between twenty four inches apart to thirty six inches. This spacing wasn't just randomly chosen either. Engineers actually ran simulations using something called computational fluid dynamics to figure out what would give best results. The goal here is simple enough really: make sure water gets distributed evenly throughout whatever area needs treatment, allowing it to evaporate completely before ever touching anything else.

Understanding the Science of Evaporative Cooling in Open-Air Environments

The magic behind evaporative cooling lies in something called latent heat of vaporization. Basically, every single gram of water that turns into vapor pulls about 2,257 Joules worth of heat right out of the air around it. Now here's where things get interesting - dry climates make this whole process work much better. When the relative humidity drops below 30%, evaporation happens roughly three times quicker compared to those sticky, humid days above 60% RH. Getting the most out of evaporative systems really depends on matching droplet sizes to what's going on outside. For instance, 30 micron mist particles perform great when temperatures hit around 90 degrees Fahrenheit with 30% humidity. But if it gets hotter, say 110°F and only 15% moisture in the air, then smaller 15 micron droplets actually give better results. It's all about finding that sweet spot between particle size and environmental conditions.

Designing Effective Misting Layouts for Maximum Coverage and Efficiency

Mapping Cooling Zones in Large Outdoor Areas

Good park design starts with creating different zones that match how people actually use the space and where the sun hits it. For example, areas where lots of people sit need about 30 to 50 percent more sprinklers packed together than regular paths through the park. The shady spots can get away with around 20 percent fewer sprinklers since they don't dry out as fast as those sunny patches. According to research published by ASHRAE last year using thermal imaging tech, when designers follow this kind of zoned approach, parks end up using about 18 percent less water overall without sacrificing comfort for visitors walking around or relaxing in different parts of the green space.

Calculating Nozzle Spacing and Flow Rate for Uniform Mist Distribution

Nozzle spacing must match environmental demands:

- 12–18" spacing ensures complete evaporation within 3 seconds—ideal for dining or gathering spaces

-

24–30" spacing suits transitional zones with moderate occupancy

Flow rates should align with pump capacity, and lines are typically oversized by 15–20% to prevent pressure drops over extended runs.

Strategic Placement of Fixed-Line vs. Portable Misting Systems

Fixed stainless steel lines with tamper-proof fittings serve permanent structures like concession stands reliably. For temporary events, portable 1,000 PSI units paired with high-temperature polymer tubing offer flexibility without sacrificing performance. The Phoenix Zoo adopted this hybrid model, reducing maintenance incidents by 62% year-over-year.

Case Study: Cooling Performance in a 10-Acre Urban Park Using Zoned Misting Layouts

A Midwestern city plaza implemented sensor-driven zoned misting, activating high-intensity spray (70-micron droplets) only above 85°F. This approach reduced heat-related closures by 41%, saved 325,000 gallons of water annually, and increased visitor dwell time by 27% in previously underused sunny areas.

Choosing Between Open-Loop and Closed-Loop High Pressure Misting Systems

How Open-Loop Systems Work and Their Maintenance Demands

Open loop systems pull straight from the city's water mains without any treatment, then just let the extra water go down the drain after it's used. The good news is these setups typically come in at half the price tag compared to their closed loop counterparts. But there's a catch they guzzle anywhere between 30 to 50 percent more water each year. When there's no filter involved, minerals start building up pretty quickly too. We've seen spray patterns get noticeably worse by about 15% within just 18 months, particularly bad in areas where the water is naturally hard. Maintenance becomes a regular chore with nozzles needing cleaning every three months or so. For best results, these systems work well only in places where the water has low mineral content and when there's plenty of water available to begin with.

Advantages of Closed-Loop Systems in Water Recycling and Efficiency

Closed-loop systems recirculate filtered water, reducing consumption by 65–80%. Filtration maintains consistent 1,000 PSI pressure and minimizes scaling, even in variable water conditions. Though initial costs are $3,000–$8,000 higher due to tanks and corrosion-resistant materials, drought-prone parks often recoup this investment within four years through utility savings.

Controversy Analysis: Water Waste vs. Cooling Efficacy in Dry Heat Climates

When it comes to dry regions, open loop systems can actually cool things down by around 9 to 12 degrees Fahrenheit because they let water flow freely without restrictions. But there's a catch - these systems tend to guzzle water at about 22 gallons every hour for just 100 nozzles. On the flip side, closed loop systems aren't quite as powerful in their cooling effect, giving us roughly 7 to 10 degrees instead. However, they save an impressive 80 percent of water compared to open loops, which makes them really attractive for anyone concerned about environmental impact. Interestingly enough, when we look at places where conditions are more controlled, such as under the shade of an outdoor theater, closed loop systems perform just as well as their open counterparts. This shows why planners need to think carefully about local weather conditions and exactly how the system will be used before making a decision.

Material Durability and Climate Adaptation for Long-Term System Performance

Durability of Stainless Steel in High-Traffic Commercial Parks

Stainless steel remains the standard for commercial misting systems due to its resistance to corrosion and physical wear. Chromium-nickel alloys now available extend service life 3– longer in coastal environments, where salt exposure accelerates degradation. Unlike aluminum, these grades maintain structural integrity for 15–20 years under heavy public use.

Cost-Benefit of Polymer Tubing in Expansive Installations

Polymer tubing cuts initial material costs by 35–50%, but longevity depends on climate. UV-stabilized variants last 8–10 years in temperate regions but degrade faster in desert heat (120°F+), requiring replacement every 5–7 years. For parks over 8 acres, combining stainless steel mainlines with polymer branch circuits balances durability and budget.

Long-Term Degradation Risks from Sun Exposure and Temperature Swings

Daily temperature swings of 50°F contribute to 78% of premature system failures. In Phoenix, uncoated stainless steel nozzles developed microfractures after 18 months of UV exposure, impairing mist uniformity by 60%. Solutions such as thermal expansion joints and ceramic-coated fittings—guided by weather-resistant engineering principles—extend service intervals by 3– in stress-tested environments.

Performance in Dry Heat Versus Humid Climates: What to Expect

In dry areas, these systems can cool down temperatures by as much as 25 degrees Fahrenheit. However, when humidity levels go above 60%, the cooling effect drops significantly to between 8 and 12 degrees. Take Miami's Bayfront Park as an example in subtropical regions. The park uses pumps operating at 1,500 pounds per square inch. That's actually half again as powerful as what we see in desert environments. But there's a trade off here. These stronger pumps put extra strain on brass parts, roughly 22% more wear and tear compared to standard setups. When choosing materials for such installations, engineers need to think about two main factors at once: the pressure requirements of the system and how likely different metals are to corrode based on where they're installed.

Total Cost of Ownership: Installation, Maintenance, and ROI for Commercial Parks

Initial Installation Costs for Full-Scale Commercial Misting Systems

Full-scale commercial misting systems range from $180,000 to $500,000+, depending on park size and infrastructure complexity. A 5-acre facility may require 1.2 miles of piping and over 800 nozzles to sustain 85°F microclimates, costing approximately $335,000 (2024 Facility Efficiency Report). Costs reflect industrial pumps, corrosion-resistant materials, and extensive zoning controls not found in residential models.

The Role of Reverse Osmosis Filters in Hard Water Areas

In areas with water hardness exceeding 150 ppm, reverse osmosis (RO) filters add $8,000–$15,000 to installation but prevent 40% efficiency loss from mineral buildup within one year. RO-treated water (<50 ppm dissolved solids) preserves precise droplet sizing (10–30 microns), essential for fast evaporation and sustained pump performance.

Scheduled Nozzle Inspections to Sustain Optimal Droplet Size

Quarterly inspections keep flow rate deviations below 15%, preventing uneven cooling and inefficiency. Facilities following strict maintenance schedules report 23% lower energy costs (Ponemon Institute, 2023) due to maintained pump efficiency. Annually, 8–12% of nozzles are replaced in high-traffic parks, with polymer options offering 30% savings over stainless steel while meeting durability standards.

ROI Case Example: 3-Year Payback Period Through Reduced HVAC Load in Adjacent Structures

An urban park covering around ten acres managed to get back its investment within just over two years after putting in place zoned misting systems. The installation cost came out to about four hundred twenty-five thousand dollars, but it paid off big time. Buildings nearby saw their air conditioning systems run 34 percent less frequently, which meant cutting down on summer power usage by approximately 110 kilowatts each month. That translated into savings of roughly fifty-eight grand every year. Interestingly enough, when temperatures soared, visitor numbers actually went up by nearly 20 percent. So not only did the park save money, people seemed to enjoy hanging out there more during hot weather too. For those running similar commercial operations, understanding how regular maintenance affects ongoing expenses is pretty important for keeping things running smoothly over time.

Table of Contents

-

How High Pressure Misting Systems Work and Why They Scale for Commercial Parks

- What Defines a High-Pressure Misting System in Commercial Applications

- Key Differences Between Residential Patios vs. Commercial Spaces: Scalability and Design Requirements

- Core Components: Pump Setup, Line Routing, and 1,000 PSI Pressure Needs

- Understanding the Science of Evaporative Cooling in Open-Air Environments

- Designing Effective Misting Layouts for Maximum Coverage and Efficiency

- Choosing Between Open-Loop and Closed-Loop High Pressure Misting Systems

- Material Durability and Climate Adaptation for Long-Term System Performance

- Total Cost of Ownership: Installation, Maintenance, and ROI for Commercial Parks